Welcome to comprex® – Your Experts in Sanitary and Industrial Pipeline Cleaning

Pipeline Cleaning Excellence Achieved with comprex® Impulses

At comprex®, we proudly uphold our commitment to the efficient and sustainable cleaning of piping systems and components.

We found our roots in municipal pipe cleaning in Germany over 25 years ago. Today, our services span a diverse spectrum of applications, extending beyond the municipal sector to encompass industrial, food and beverage, pharmaceutical, dairy, drinking water, and numerous others.

In addition to pipelines, our cutting-edge technology is designed to clean a variety of inline equipment, including heat exchangers, static mixers, and a wide range of inline process components. .

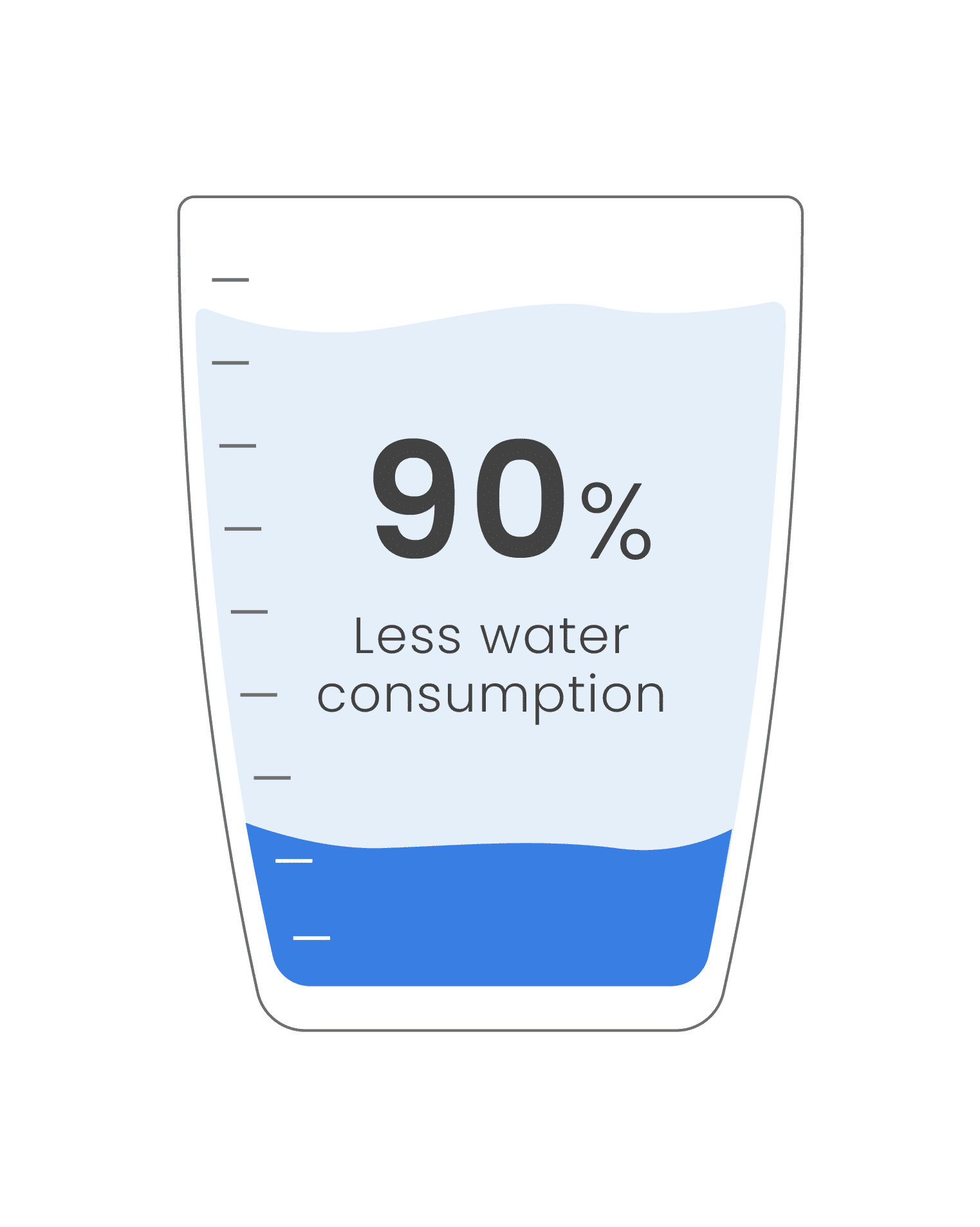

The comprex® Impulse Cleaning Process operates through a mechanical approach, harnessing pulsed compressed air and a minimal water usage. Our mission is to treat water as a precious resource, utilizing it responsibly and driving improvements in energy efficiency through our innovative CIP technology.

Hygiene is a critical aspect in numerous applications we serve. While our key differentiating factors include water, energy, and time savings, we also protect our customers from product loss due to microbial and quality issues stemming from unclean pipes, such as cross-contamination.

comprex® Impulse Cleaning provides excellent value for Clean-in-Place (CIP) services for most inline components, including heat exchangers. Our services enhance heat transfer efficiency while reducing downtime and maintenance requirements. By optimizing the cleanliness and functionality of inline components, we empower our clients to achieve peak performance and operational excellence.

We comprex your lines!

comprex® - industrial pipe cleaning and more

Simple but effective:

We specialize in cleaning a wide range of piping systems, including:

- Product lines of similar or varying diameters

- Cooling and tempering circuits

- Heat exchangers

- Plant components

- Static mixers

- Cooling lubricant lines

- Drinking water distribution networks

- Wastewater pressure lines

- And many more

comprex®: Your Mechanical Solution for Comprehensive Deposit Removal:

comprex® Compared to a conventional water flushing system

The powerful cleaning impulses generated by air and water are not only highly effective but also consume up to 90% less water compared to a traditional water flush.

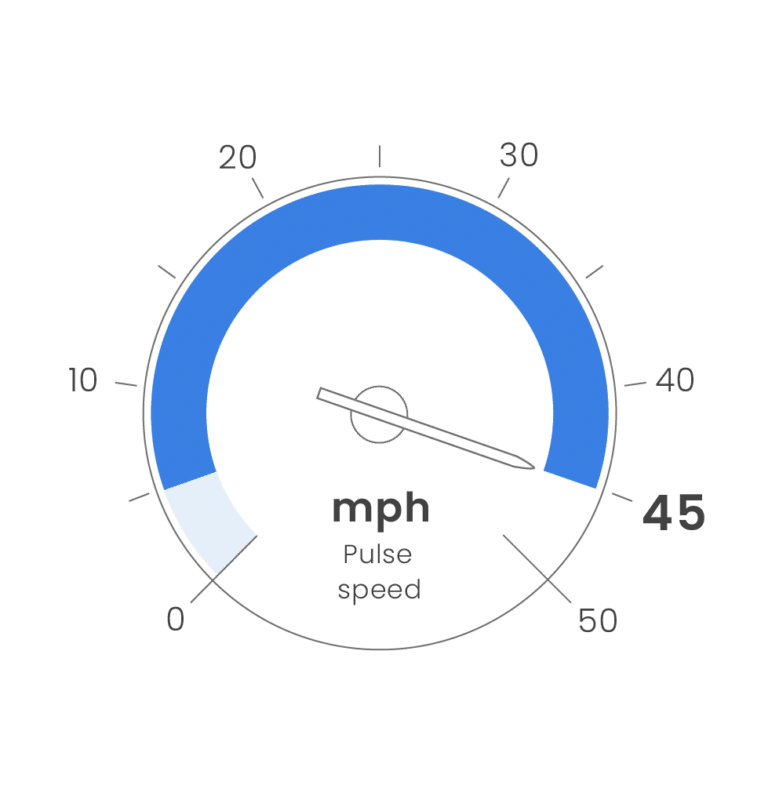

The comprex® impulses propel at speeds of up to 44 mph within the pipeline in contrast with traditional flush speeds of 6 mph.

44 mph = 65 ft/s

6 mph = 9 ft/s

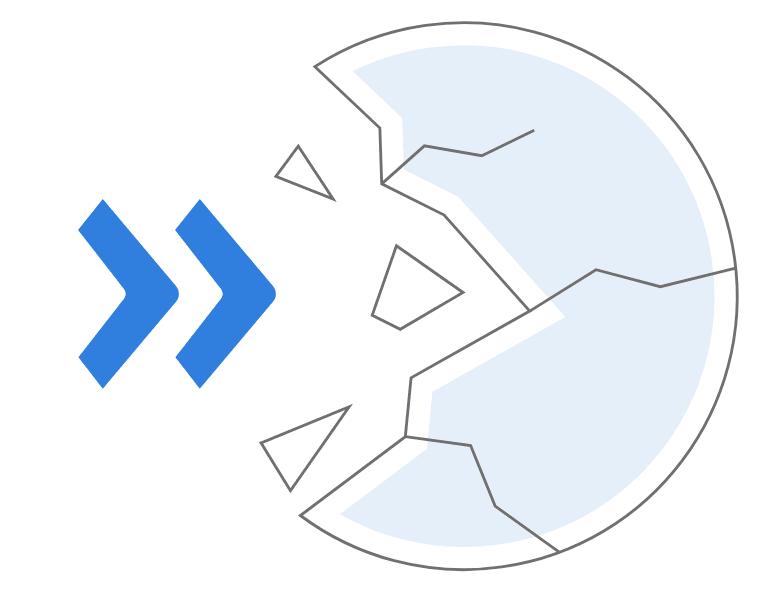

The mechanical cleaning forces applied to the internal surfaces of process lines and components are significantly amplified, reaching up to 100 times the strength of water rinsing when utilizing comprex®. Surprisingly, despite this intensified cleaning power, our process is gentle on the pipelines, as the pressure remains well below the system’s operating limits

We comprex your lines!

Efficient cleaning without any chemicals

No Chemical Required

Water Savings

MODULAR design

FLEXIBLE

POWERFUL

Efficient

Why should you choose us?

With our comprex® process, we offer an effective, sustainable and efficient cleaning alternative.

The comprex® process is versatile:

At a Glance: Our Industry Solutions

Service

With comprex®, we excel in effectively cleaning intricate piping systems with unique demands. Our expertise spans across various sectors, from metal, plastic, and paint production to highly regulated pharmaceutical, food, and chemical industries, offering exceptional industrial pipe cleaning solutions.

Applications:

Pipelines

Product lines

Cooling and temperature control systems

Machine cooling

Cooling lubricant

Heat exchanger

New installations

Engineering

At comprex®, we take pride in our dedicated team of engineers who play a pivotal role in our comprehensive services. Our engineers are not just problem solvers; they are solution architects. Here’s how our engineering team ensures your needs are met:

1. Application Evaluation:

Our experienced engineers thoroughly evaluate new customer applications. This meticulous assessment allows us to define and optimize cleaning solutions, whether they are portable or permanent. We recognize that each application is unique, and we tailor our services accordingly.

2. Validation Services:

We understand the importance of validation, especially in industries with stringent regulations. Our engineering team provides validation services to ensure that our cleaning applications meet the required standards and performance expectations.

3. Root Cause Analysis:

Sometimes, solving a problem requires going beyond the surface issues. Our engineers excel in identifying the root causes of problems. By delving deep into the challenges you face, we can develop long-term, sustainable solutions.

4. Life Cycle Cost Reduction:

At comprex®, we believe in providing solutions that not only address existing issues but also reduce the life cycle cost of operation. Our engineering team looks at the bigger picture and implements strategies that lead to cost-effective, efficient, and sustainable results.

In essence, our engineering team at comprex® is your partner in innovation and problem-solving. We are committed to delivering reliable, long-lasting solutions that meet and exceed your expectations.

Applications:

Paint and varnish industry

Chemical industry

Plastics processing

Food and Beverage

Pulp & Paper

New installations

comprex®

Competence Center for Mechanical Cleaning

At the core of our mission lies the patented comprex® Impulse Cleaning Process, a technology we continually refine and expand across various performance levels. This flexibility enables us to tailor our solutions precisely to the evolving needs of our clients. As a service provider specializing in the cleaning of fluid-carrying systems and a manufacturer of both mobile and stationary cleaning systems, we’ve been serving diverse sectors within the drinking water supply and industry since 1997

Practical examples, Professional articles and publications

We keep you up-to-date with regular updates on the latest developments and innovations.

Explore practical examples across various sectors on our website.

Learn more at comprex.de.